PLEASE NOTE: The below tips predominantly apply to the legacy Joto pen and ink system. If you have the Easy Fill kit we highly recommend using it instead.

There are a number of factors that can effect how quickly Joto’s ink dries out, check out our tips below to make sure your Joto is setup for best results.

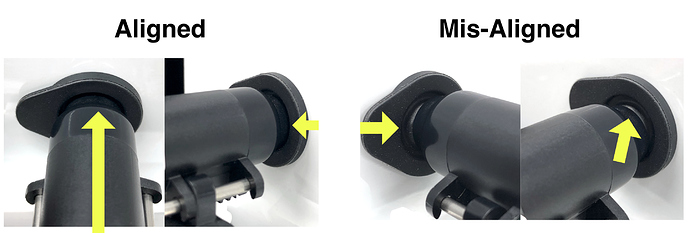

Dock alignment

Joto’s dock acts in just the same way as a pen lid and like most marker pens if the lid isn’t aligned correctly the ink will dry out.

When the pen is sat idle in the dock the pen should sit centrally as shown in the picture above. A small misalignment could lead to the ink drying at a much faster rate.

If you notice the pen isn’t positioned accurately in the dock then the most likely cause is a misalignment with Joto’s arm. If you see this with your Joto please submit a support ticket at support.joto.rocks and we’ll take you through the steps to realign the arm.

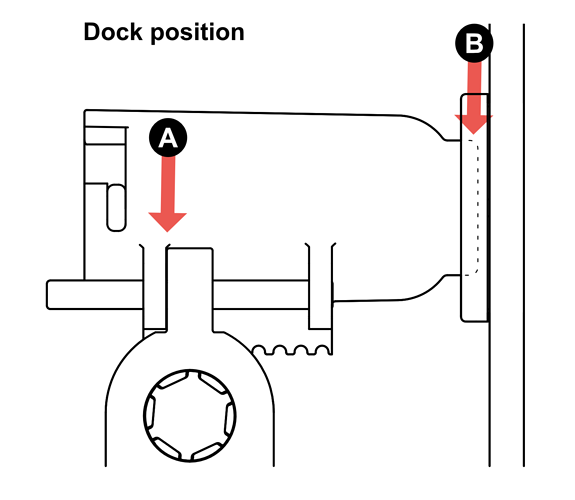

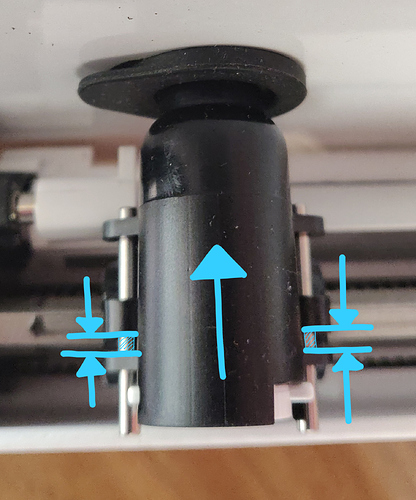

Pen Calibration

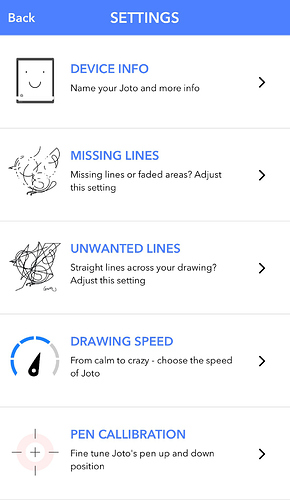

The second step to ensure an optimum seal between the pen and the dock is to run the calibration routine in the app settings.

When the pen is sat idle in the dock it’s crucial that the pen rests right against the dock with no gap. The easiest way to check this is to look closely at the position of the pen on the little metal rails. See position ‘A’ in the diagram above, there should be no gap between the two plastic parts here, if you can see the metal rails in this gap then the pen needs calibrating.

The pen position will update live as you alter the position in the app. Once you have set the first calibration position click next step. The second step is the most critical for ensuring a good seal between the pen and the dock. The default dock position is 140. By increasing this number you’ll move the pen closer to the dock. We expect the average range of this position to be around 140-170 but in some cases it may be higher. Once the gap between the pen and dock is closed you can save position and run a test Jot.

The calibration will also reset the pen up and down positions for drawing. If you notice unwanted lines during the test Jot or if the pen isn’t touching the surface, head back to the settings and you can adjust the pen position using the missing and unwanted line procedures.

If you run into any trouble setting the pen position, submit a support ticket and we’ll help you get everything back up and running as soon as possible.

Ink refilling

When filling the ink reservoir can keep dripping ink onto the sponge until it takes up to a couple of seconds to absorb. This ensures it’s fully saturated and is able to transfer that ink to the nib. Under-filling the reservoir will cause the ink to dry prematurely. If the nib has dried out at any point it can lose the capability to absorb much if any fresh ink. In this case it may help to swap to a fresh nib and reservoir. Keep hold of your used consumables, we’re looking into methods for refreshing these used parts.

Ink Longevity

If Joto’s ink is drying out in 1-3 days then the calibration steps above should greatly improve the situation. However we’re aware that even on a well calibrated machine some users are experiencing the ink evaporating at a much faster rate than expected. Due to some variations in the manufactured parts and some necessary part changes we believe this has caused the entire ink assembly to not perform to the initial standards set for Joto. We’re working hard to overcome this issue and accelerating the development of our bespoke pen refill system.

Look out for a beta test sign-up if you’re interesting in helping us test the updated system.