Easy Fill development

This thread has been copied from the old community site. It’s to serve as an archive for our work to develop the improved Easy Fill pen kits.

From all the feedback we’ve received it seems the pen is drying out for 3 reasons:

-

Pen not calibrated or mounted in the incorrect position at the factory.

-

Pen bouncing back once it returns to the dock - we’re looking into the cause of this and will fix either through firmware or mechanical adjustments.

-

Variations in manufactured parts not making a tight enough airtight seal - if you’re pen is drying out in 1-2 days, I would assume its actually for reasons 1 or 2. If its drying out around 4-5 days, it is probably likely to be this reason.

@Gernot - great work looking into this issue, super helpful testing we can work with. We’re also looking at similar solutions. Let us know how your tests go.

If you have this problem - the most helpful thing you can do is send us a picture in a support ticket of your pen position when its in the dock. We can help both diagnose your problem, and also collate a much better picture of what might be causing the issue.

We’ll be putting out an update shortly on KS and Indiegogo, but lets keep the conversation going here as well.

Just to let everyone know on this thread we’ve added you to the pen beta testing program we’ve just announced in our most recent update. We’ll be sending you our prototype for the new easy fill system to say sorry in some way for the frustrating start, but also as a thank you for all the helpful feedback. We will be asking for some feedback and testing. If you’d rather not be involved just drop us an email at supprt@joto.rocks

“Looking forward to seeing the prototype! The new app updates look good (as seen in the kickstarter update screenshots - certainly increases joto’s functionality. Thanks for listening guys, onwards and upwards I reckon for us Jotters!”

Gareth Ingram

Hi guys, quick update on the developments with the pen and ink system - We’re at the point where one route in particular is showing a lot of promise and we’re putting our efforts into thoroughly testing this option. We want to get prototypes sent out to our list of Beta testers as soon as we can but understandably we also need to know all the variables and be confident the parts you receive will work as expected.

In case you’re interested, here are some of the things we’ve been working hard on:

-

Explored as many options as we can for a quick DIY fix to extend the ink longevity.

-

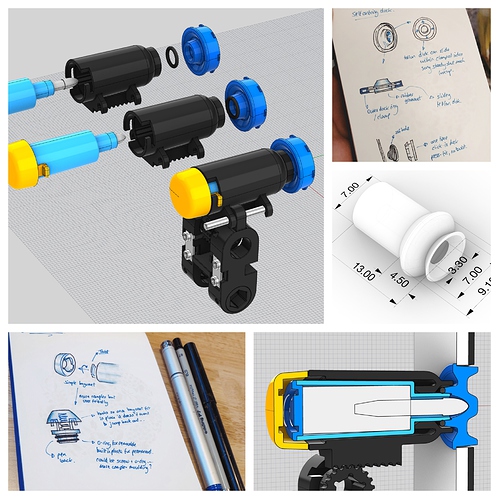

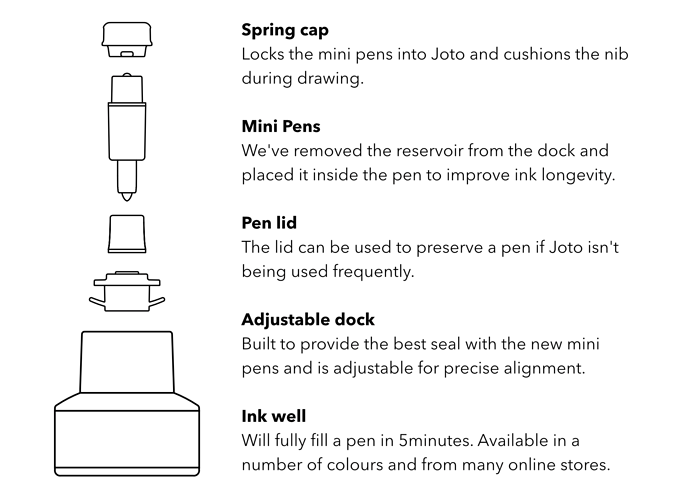

Created an entirely new pen assembly with captured spring that will retrofit to existing Joto’s.

-

Moved the ink reservoir inside the pen so that it isn’t exposed while jotting.

-

Designed an adjustable dock that can be aligned to exactly match the pen position.

-

Modified the nib holder design for compatibility with off-the-shelf inkwells. This means mess-free refilling.

-

With two pens you can easily swap them between Joto and the inkwell so there’s no downtime when one pen is running low on ink.

-

Iterated on the new plastic parts with SLS 3D printing, sealing all components with CA glue.

-

Ran longevity tests on the nib and ink reservoirs so we can calculate the exact number of Jots you can expect to produce before swapping pens.

-

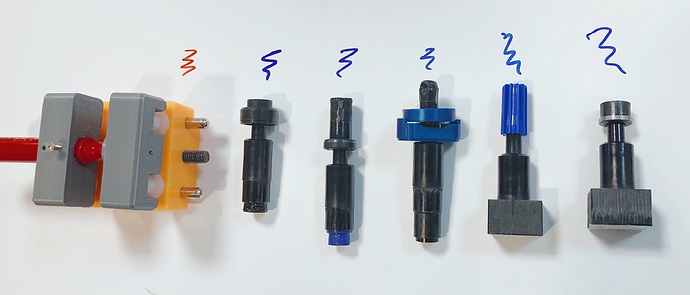

Created a series of prototypes to compare methods of sealing the pen between Jots.

-

The current front-runners for creating a pen seal are - Vacuum bellow pads (thanks to backer Simon Jelley for the suggestion) and silicone earbud tips which happen to be a perfect fit for the pen.

-

Built custom jigs to compare pen seals and tested the ink status at consistent intervals.

Tests are ongoing for the new system but we’re getting much closer to a final design.

We want to say a big thanks to those of you contributing ideas and suggestions in this thread and through the support tickets. There’s such a wealth of knowledge in this community and fortunately we’ve been able to put some of these stellar ideas into practice.

Finally here’s a little snippet of some of the behind the scenes work that’s going on -

Quick pen update - We’ve been focused on refining the seal between the new pen design and the dock which is a bit more complex than it might initially seem.

Something you may not have noticed the last time you clicked a lid onto a pen, is quite how much force is required to snap it into place. It’s much greater than most hobby servo motors can handle. Our challenge is to create the same level of seal with a much lower force (which unfortunately the current Joto design isn’t doing reliably).

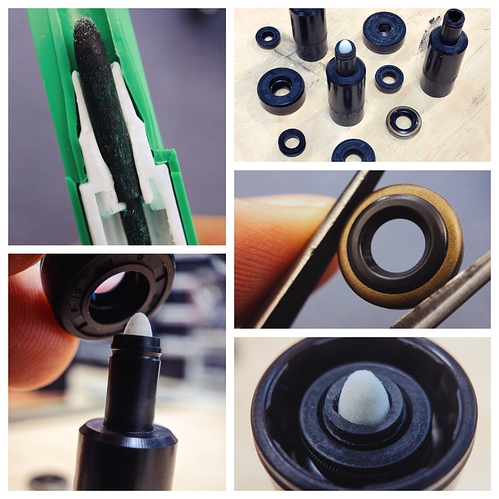

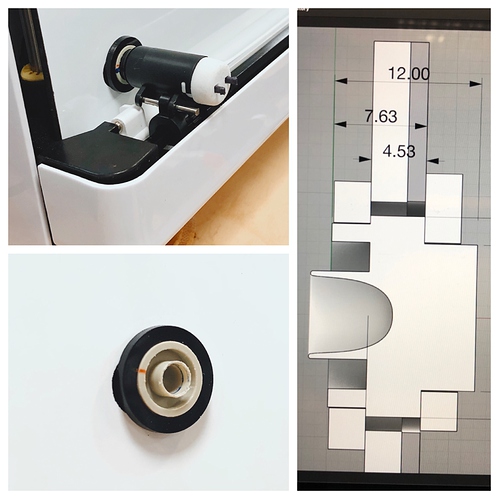

The way we’re trying to solve the problem is to develop a more forgiving flexible seal for the dock which with a lower force will compress and reliably align with Joto’s pen every time. We’ve been testing as many off-the-shelf seals as we can including vacuum bellows and earbud tips which we showed in a previous post.

Having tried and tested a large number of seals we’ve realised that pressing Joto’s pen onto or into a flexible seal isn’t providing the consistent results we’re looking for. So with our latest prototypes we’ve introduced features that allow Joto’s pen to ‘snap’ into the seal much like a standard pen lid (Notice the small groove machined near the tip of the parts below).

Other improvements include a refinement of the pen tip so that it comfortably connects with the refill station/ inkwell and increased air channels along the length of the nib for better ink flow while drawing and refilling. Tests for the new dock seal are underway and we’ve received quotes for manufacture. More to come soon.

“Wow guys - great progress ! The snap looks (sounds) promising. Certainly a challenge to get the last um right to balance with force & tightness; but with your experience no problem ;-)”

Gernot Abel

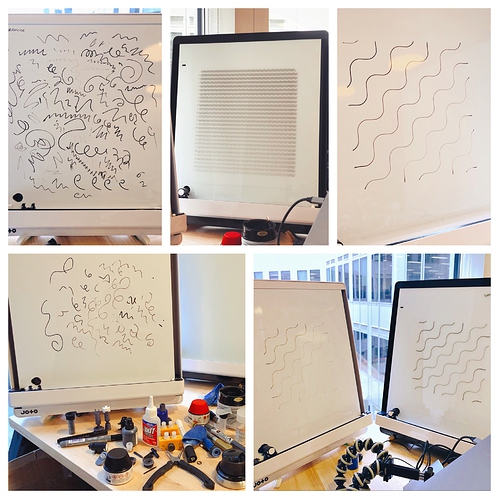

A little more behind-the-scenes. We’ve continued to narrow down the options – as you can see the testing at this stage still isn’t pretty! Once we’ve found the optimal solution to keeping Joto’s pen fresh the final design will come together quickly. As frustrating as it is, the more we improve the seal, the longer it takes to test, but it’s encouraging that we’re getting closer to a final design.

Pen and ink progress update -

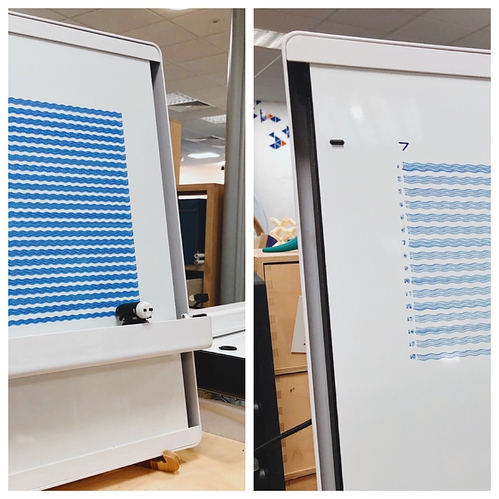

With our latest pen design we wanted to understand how much ink the pen could store and how that translates into real-world usage. So we set about conducting a couple of tests to compare against our estimates.

Firstly we wanted to see with a fresh pen how many Jots you could draw in one go. To begin with we inserted a freshly machined and assembled pen into an off-the-shelf inkwell where it fully saturated itself with ink in just a few minutes. Then we ran our drawing torture test which involves Joto drawing blocks of wavy lines over and over and over again. For me the easiest way to think about ink usage is in terms of length of line drawn, in this test each wavy line is 250mm long and is drawn in blocks of 4, so 1m per block.

The torture test took longer than expected which is a good thing for such a small pen! The test was stopped after completing just over 180m of lines, at this point the pen was still drawing but subjectively the lines had faded to the point I would want to top up the ink. So what does 180m of lines look like? During manufacture we used the ‘Walking man’ Jot by renowned illustrator Burnt Toast to test units coming off the production line so I thought it would be a good Jot to reference for ink usage. The curves that make up the Walking man total 1.7m in length which based on our torture test means one pen holds enough ink to draw roughly 100 of them, not bad?

The idea is that once you’ve drawn around 100 Walking man’s the pen can be swiftly swapped for a fresh one and the empty pen placed back into the inkwell for refilling.

The next stage is to re-run this test but spreading the drawings out over a few weeks so that we can be sure the seal with our new dock is keeping the ink fresh between drawings. We’re just over a week into this test and it’s going really well

The results are looking good so in the meantime i’ve hopped on a flight to China to start refining the design for tooling with experts in injection moulding. More updates from China coming soon.

“Great work! You deserve to have this thing take off so glad to see you on your way!”

Aaron Green

Hi guys,

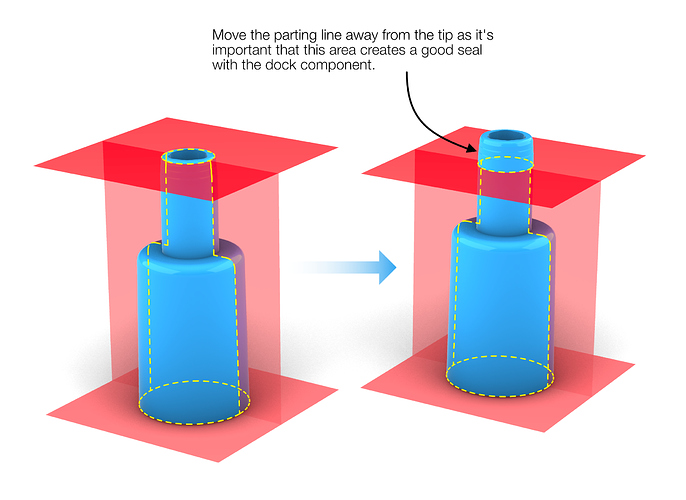

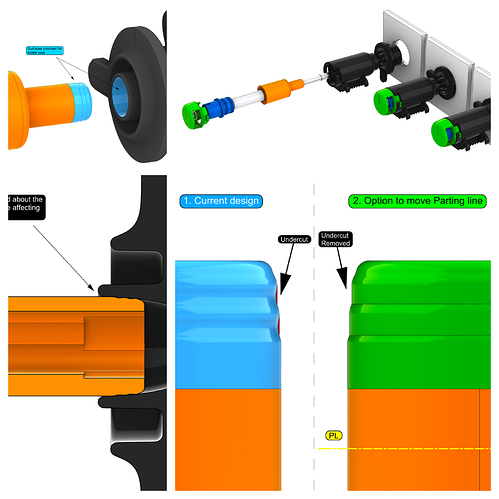

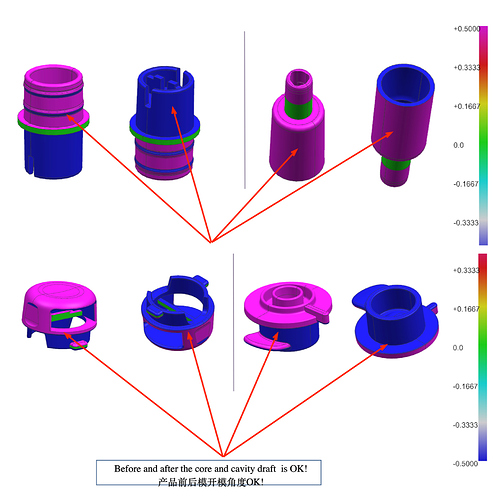

I’ve been working with our tooling supplier to refine the design of the new plastic pen system components. This includes selecting areas of the tool to be polished, trying to create even wall thicknesses (to avoid sink marks), negotiating draft angles and moving parting lines.

We’re validating a couple of design changes with another round of 3D printed and CNC’d parts before we kick-off the tooling. It’s been a bit of a rush to agree the design changes this week before Chinese national holiday begins but we’re expecting the prototype parts back just after the holiday. I’ll have more updates once these parts arrive!

I wanted to share some of the diagrams created by the tooling supplier and myself to communicate our ideas back and forth. If you couldn’t tell, our tooling supplier has a thing for red arrows whereas I’m more into shiny highlights and dotted lines. Enjoy.

Quick update on the new pen kit -

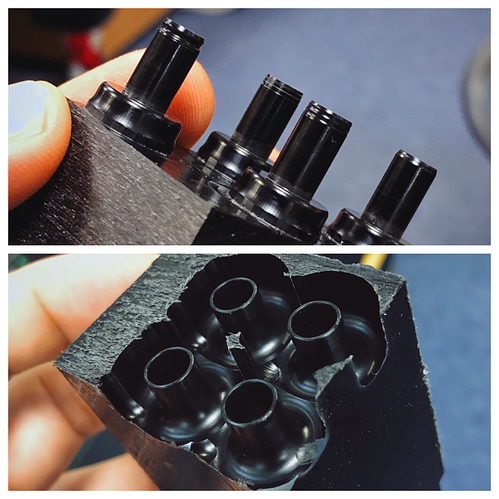

Just yesterday our tooling supplier sent us the first images of our injection moulded sample parts. The parts first need to pass the suppliers internal quality control check before we can begin our own testing in the next couple of days. We’ll be checking that tolerances are up to standard before we go ahead with the first batch, but we’re pushing to get this done as soon as possible.

I recently spent some time at the tooling factory in Shenzhen and got to see the progress of our tool in person. For those interested the shiny parts pictured below are our own copper EDM electrodes for the pen tool. The electrodes are used to erode the tool steel making geometries which would be difficult or impossible to make through conventional machining. We’re moulding 5 small components in the same tool so it requires quite a few electrodes to make all the features we need.

Multiples of each electrode are machined in case one gets damaged or eroded too much in the EDM process

It’s finally here!

I’m happy to announce we’ve just received the first sets of the new Easy Fill kit – the much improved, mess-free, longer lasting and simplified ink system for your Joto.

At the core of the Easy Fill kit are our new mini pens, which soak up ink from a standalone inkwell which means mess-free & hands-free refilling. The kit includes two mini pens so you can quickly alternate between refilling and jotting.

To say thank you for being active members of the Joto community, we want those contributing to this thread to be the first to receive the new kit. If you email your postal address to ‘hello@joto.rocks’ we’ll get an Easy Fill kit sent over.

We’ll be sending a bigger update out next week so stay tuned.

Happy Jotting!

“Awesome & a pleasure to be part of this crowd”

Gernot Abel

“Hey all, I’ve had the new pens nearly three weeks now. After 23 days of usage, I’ve now only had to add a new pen. It works great, one pen in the joto, the other in the new ink bottle. Every image crisp, even leaving it for a few days with no drawing, as soon as I send a jot its up and at em’ - The team has fixed this problem in my opinion - pen seals every time when it returns to the dock. On top of this, the SVG imports are amazing. I have a membership on adobe stock and access to soooo much line art, now constantly creating Jots. Hang in there, once you get the new pens you will not be disappointed.”

Vincent Haywood

“SVGs - brilliant! this is really increasing the functionality of Joto

The new app and pen update is fantastic. I had a brief period when I didn’t line the cap and pen perfectly, which resulted in it drying out quickly, but with a slight readjustment I have been up and jotting ever since! over two weeks of use (with fairly substantial designs) and I’m only starting to think about topping my pen up!”

Gareth Ingram

“New pen arrived and installed within a few minutes and first drawing completed with great contrast

Fingers crossed that’s an end to the pen drying saga now time to get Joto’ing

Hope you all get yours soon”

Mark Copp

Fingers crossed that’s an end to the pen drying saga now time to get Joto’ing

Fingers crossed that’s an end to the pen drying saga now time to get Joto’ing